Explore okkura's cutting-edge 2025

OKC range of digital cutters, where incredible cutting precision meets ultra-fast speeds! Designed to work with a wide variety of materials—ranging from carbon fiber and glass fiber to foam, leather, rubber, textiles, and cardboard—our cutters are available in four versatile widths: 1,600 mm, 1,800 mm, 2,500 mm, and 3,200 mm. This adaptability empowers you to select the ideal size that fits your materials and workspace, whether you prefer a conveyor setup or a static bed. Our 1,600 mm and 1,800 mm models even offer our revolutionary Auto Contour Cut and Cut Path Projection technology!

Boost your production efficiency with our all-encompassing cutting solution that optimizes your workflow and maximizes your machine's output. Plus, our customized service and maintenance packages promise minimal downtime. Take advantage of the chance to streamline your cutting processes with Okkura—let’s transform your production today!

OKC1800 RANGE

OKC1600 RANGE

OKC2530

OKC3234

SPECIFICATIONS

-

Power 11kw overall

-

Dual or Single tool head option - combined with the following head options

-

Electric oscillating knife

-

Pneumatic oscillating knife

-

Power rotary knife - round/polygons

-

Creasing tool - 3 wheel sizes 55mmd, 35mmd, 30mmd

-

Marker pen holder

-

Punching hole tool

-

Kiss cut tool

-

Variable angle speed V-cutter - angles 45, 30, 22.5, 15, 0

-

Tangential knife

-

-

Safety devices infrared induction beams to X + Y, Tool Head Safety Guard

-

Cutting speed Max. 1200mm/s (can be varied according to different material thickness density

-

Movement speed Maximum 1500mm/s

-

Cutting material Corrugated paper, PVC foam core sheet, thick foam, grey board, paperboard,Vinyl adhesive , etc.

-

Cutting thickness Maximum 20mm (set according to different materials and tools)

-

Vacuum table 9kw vacuum absorption with felt / PU - variable

-

Repeated positioning accuracy ±0.05mm

-

Mechanical Precision Maximum 0.05mm

-

Drive system Mitsubishi / Taiwan Delta / servo motor, Taiwan PMI linear guide rails

-

Control system OKKURA touchscreen controller

-

Transmission XY by rack and pinion, Z axis and rotary seat by ball screw

-

Data transmission method USB port or Ethernet

-

Support file DXF,PLT,AI,SVG,PDF,NC,DST,DSB, etc.

-

Operation environment Temperature 0-40℃, Humidity 20%-80%RH

-

Voltage 380V/220V/50Hz/60HZ

-

Optional Auto Contour Cut - ACC

-

Optional Cut path Projection - CPP

TOOL OPTIONS

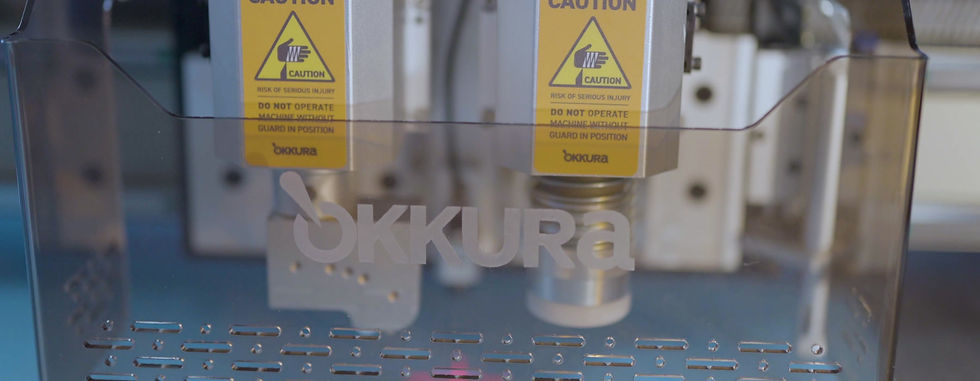

OKKURA OKC machines can be specified with either dual or single tool head mounts combined with a comprehensive range of powerful cutting tools and blades providing solutions for most material cutting applications. We will asses your material/s and products that you want to cut and recommend tools and blades for your cutting application.

We are here to help you find the perfect cutting solution.

SAFETY

We have incorporated as standard a number of automatic and manual safety stops along with tool guards that will help keep both the operator and workspace safe. Okkura digital cutters come fitted as standard with:

-

automatic detection beam located across the front of the cutting head detects human hands or foreign objects and disables the machine within .01 seconds and remains disabled until the restarted from the control panel.

-

Proximity sensors are located at the end of the X axis beam again these will disable the machine until reset.

-

Emergency stop buttons are located on each corner of the cutter, the machine will require resetting if pushed. You can start the cutting process again from the stopped position.

TRAINING

We include a training package as part of the machine delivery process. This includes machine familiarisation, health and safety briefing, software introduction both on machine and SAI Flexi integration packages. This can be completed on site or at our head office in Buckinghamshire

with your nominated operator/s. When we leave the installation site your operator will be

confident and capable of operating your OKKURA digital cutter. We can also run further on-site

operator advanced training courses, usually a few weeks after the initial sessions. This allows the

new operator to get used to the machine basics and work out where further training would be helpful. There will always be questions about machine operation and we will always be

contactable to help you. This is all part of the OKKURA experience, we want our machines to

increase productivity and streamline your manufacture process. This can only be done with

the right information, support and training.

SERVICE & SUPPORT

We offer a choice of three comprehensive support packages for your OKKURA machines. These support packages are designed to keep your machine in good working order and to give you peace of mind, while ensuring you're kept operational.

Package selection can be calculated by type of machine use, i.e what material/s are being cut, and number of predicted hours use.

GOLD LEVEL SUPPORT

Call-out, 6 hour Telephone/video call response, 72 Hour on site response (3 working days), Two routine maintenance visits per year. In the event of a call-out. All travel time would be charged at cost less 15%. Time on site, travel costs and parts would be invoiced separately at current list prices. This support level can be customised to suit your requirements such as same site multiple machine servicing.

SILVER LEVEL SUPPORT

Call-out, 3 Hour Telephone response, 48 Hour on site response (2 working days), Two routine maintenance visits per year, all travel time, travel costs and 1st two hours of any call-outs. Any additional time on site and all parts would be invoiced separately at current list prices.

BRONZE LEVEL SUPPORT

Call-out, 3 Hour Telephone response, 48 Hour on site response (2 working days), travel time, travel costs, time on site, parts and two routine maintenance visits per year

UNIFIED PRODUCTION

To streamline the cutting production process we have developed a unified production material handling system. This includes close proximity vertical material storage, automated material feeding, to post cut work station and combined waste hopper. This combined system speeds up production and reduces operator fatigue and risk of injury.

OKC1825U - CPP & ACC option, material feeder and vertical storage + cut material work station

OKC1825

OKKURA SACRIFICIAL CUTTING MATS

Extend the life of your cutting surfaces by overlaying our sacrificial cutting mats. They are cost effective fast to install and easy to swap.

Enabling better cutting and preventing material cross contamination.

8 types of sacrificial matts to match

your cutting requirements and sizes

2mm can be used on top of conveyor belts for additional protection…

•

3mm mats on their own as cutting underlay

•

5mm is for oscillating cutting - it can be flipped over when front face is degrading and used on reverse side to extend the life

~1mm cutting depth in underlay.

•

All 8 types can be supplied to any length

“soft” versions are stiffer than you think and are excellent for textile applications giving more counter-force from underneath improves rotary or oscillated application - enabling better cut.